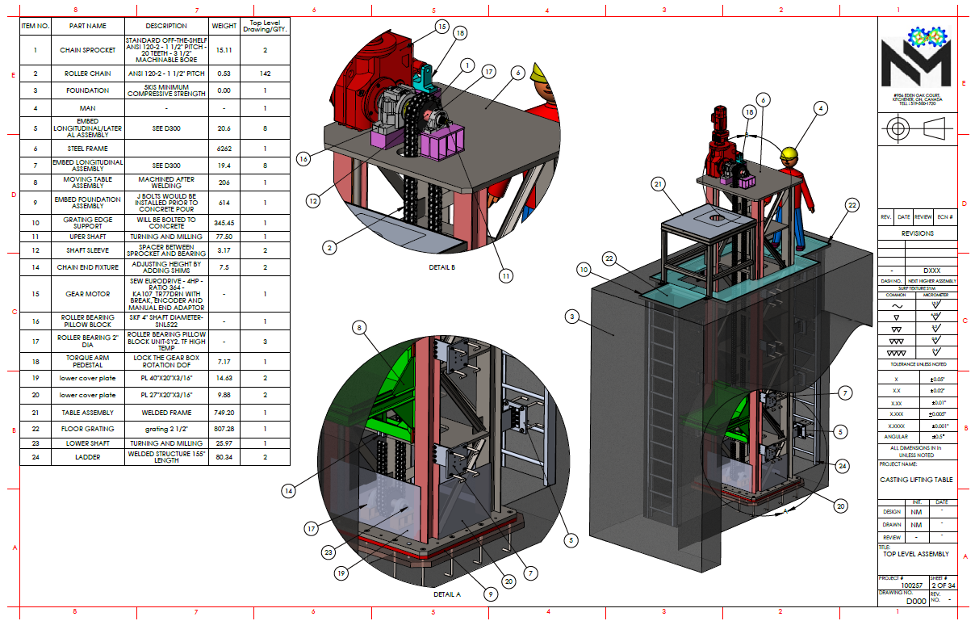

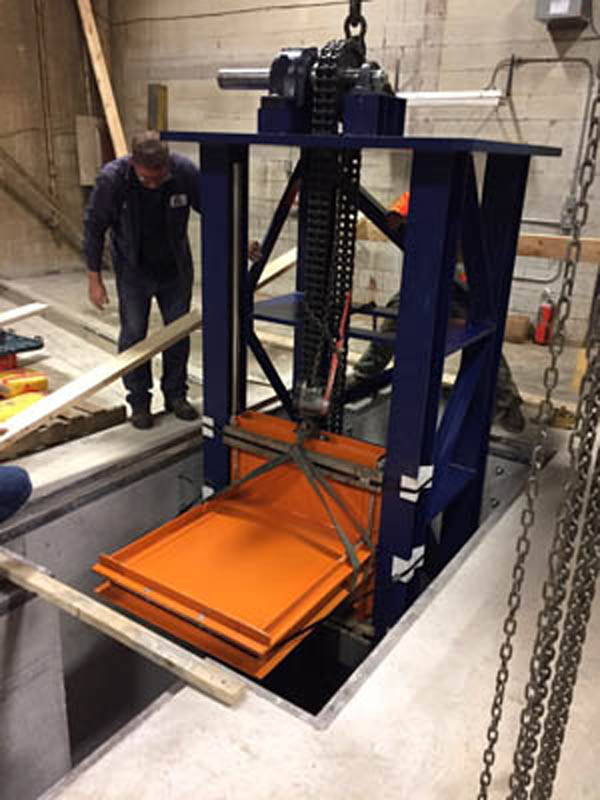

Project Overview

NM Engineering designed and fabricated a vertical custom casting machine tailored for our client in Brantford, Ontario. The system features a 17-foot stroke with ±0.008” lateral deviation. The power mechanism, utilizing a chain and sprocket, supports a maximum load of 5,000 lbs and operates at a speed of 20 ft/min. All connections and foundation designs were created in accordance with CSA Concrete Standard A23.3-04. The system is used for continuous casting of aluminum rods and alloy rods, primarily for the automotive industry.

Key Benefits

- Precision and Flexibility: Capable of handling various rod and pipe diameters and wall thicknesses, offering versatility for different product specifications.

- Maintenance-Free Design: Engineered to be maintenance-free, ensuring long-term reliability and reducing operational downtime.

- Efficiency and Cost-Effectiveness: By eliminating extra production steps, continuous casting saves time, energy, and reduces waste, lowering overall production costs.

Challenges

- Accuracy and Speed: While the requested lateral accuracy was ±0.01”, we achieved a higher precision of ±0.008”, which required advanced engineering to maintain high-speed operations at 20 ft/min.

- High Temperature and Cooling: The casting process operates under extreme temperatures, requiring precise cooling control to ensure consistent metal quality.

- Constant Speed: Maintaining a constant speed during casting is critical for uniform product quality, demanding advanced control of the power mechanism.