Projects

One million-pound GERB Tuned Mass Damper in Uptown Manhattan

The skyline of Midtown Manhattan, renowned for its towering edifices, saw a significant advancement with the installation and commissioning of a million-pound tuned mass damper. This mechanical marvel was meticulously designed and installed to match the as-built frequency of the skyscraper, ensuring its stability and resilience against dynamic forces such as wind and seismic activities.

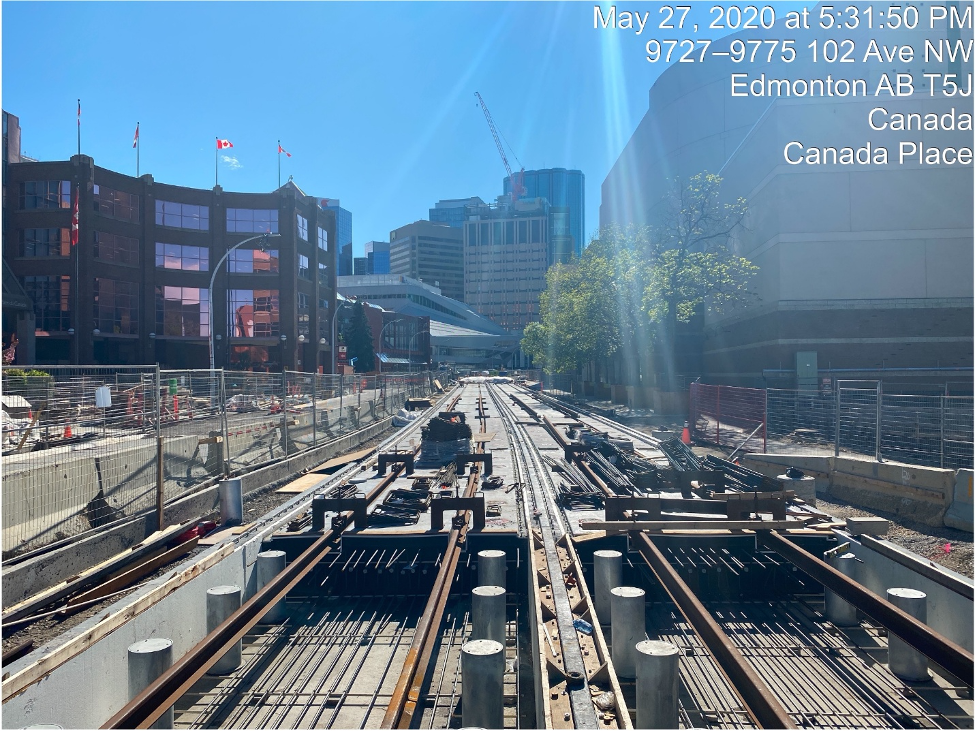

GERB Floating Slab Track – Valley Line LRT, Edmonton, Alberta

The Valley Line LRT is an ambitious 13-kilometer rail project awarded to TransEd Partners with a budget of approximately 1.8 billion. This design-build endeavor includes a 30-year operational commitment, with the initial lines marking a significant milestone in modern urban transit development.

Half a million-pound GERB LFRS Tuned Mass Damper in Uptown Manhattan

Low friction rail system TMDs offer cost-effective, compact designs with tuning capabilities for different frequencies in x and y directions. Designed to match the skyscraper’s as-built frequency, this mechanical marvel ensures stability against wind and seismic forces.

GERB Tuned Mass Dampers at Boston University – CCDC Campus

At Boston University’s newly built CCDC Campus, ensuring structural stability and user comfort was a key priority in the design of a six-story building with a central monumental stairway. To mitigate vibrations caused by heavy foot traffic, a series of Tuned Mass Dampers (TMDs) were strategically installed beneath the stairway landings, providing an effective and long-term solution.

20 Ton GERB Tuned Mass Damper – Grand Quay Observation Tower, Montreal

Installed a 20 ton, tuned-mass damper in a cantilevered structure at Port Montreal. This state-of-the-art observation tower located at Montreal’s waterfront, provides breathtaking views of the city and some of Grand Quay’s many attractions.

GERB Tuned Mass Dampers at Totem Lake Connector Bridge in Kirkland, WA

Bridges are designed to be strong and resilient, but even well-engineered structures can experience vibrations from pedestrian foot traffic. The Totem Lake Connector Bridge connects a hiking trail to a new subdivision and faces significant foot traffic from hikers, runners, and cyclists.

GERB Tuned Mass Dampers at Waller Creek Bridges, Austin, TX

Bridges are designed to be strong and resilient, but even well-engineered structures can experience vibrations from pedestrian foot traffic. At the Waller Creek Bridges in Austin, TX, this challenge became evident, prompting the need for an effective vibration mitigation solution.

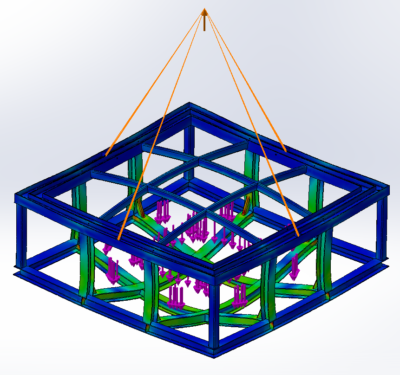

20 Tons Shipping Crate – GE Canada

For GE Canada, we designed and fabricated a specialized shipping crate to transport a 10-tonne machined turbine bearing. The crate, weighing 1,500 kg, was designed to be handled with four slings and shackles, with the bearing stored inside without any support on the bottom.

Continuous Vertical Casting Machine

NM Engineering designed and fabricated a vertical custom casting machine tailored for our client in Brantford, Ontario. The system features a 17-foot stroke with ±0.008” lateral deviation. The power mechanism, utilizing a chain and sprocket, supports a maximum load of 5,000 lbs and operates at a speed of 20 ft/min.

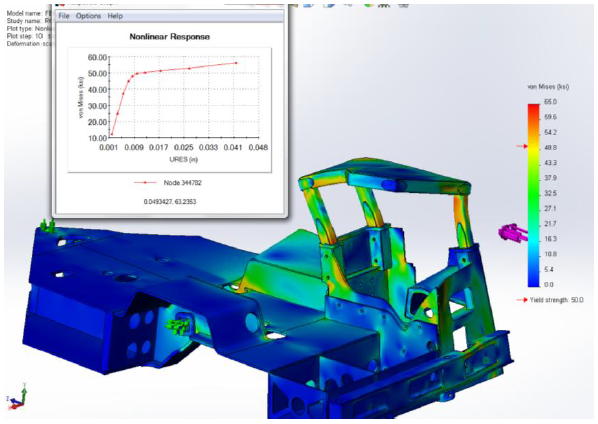

Mining Machine Design for Underground Drilling and Bolting

NM Engineering developed the mechanical design for a mining bolter machine used in underground drilling and bolting operations. The design, analysis, and calculations were performed in accordance with CSA standards to ensure safety and reliability in harsh mining environments.