Project Overview

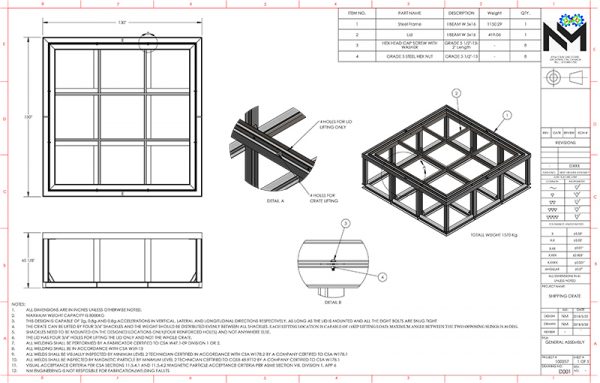

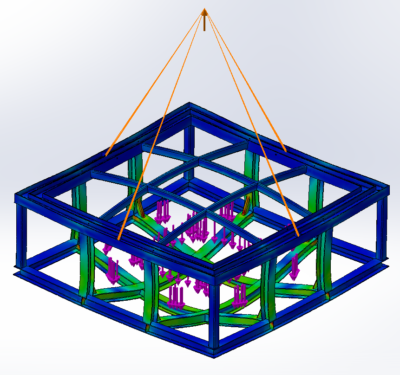

For GE Canada, we designed and fabricated a specialized shipping crate to transport a machined turbine bearing. The crate, weighing 1,500 kg, was designed to be handled with four slings and shackles, with the bearing stored inside without any support on the bottom. This required precise structural considerations to ensure stability and safety during transit.

The Challenges

1-Heavy Design Load:

One of the primary challenges was that the shipping crate needed to withstand a total load of 36 tons—24 times the weight of the crate itself (1,500 kg). This massive design load required detailed calculations and precise engineering to ensure the crate could endure such extreme forces during transportation, particularly longitudinal, lateral, and vertical accelerations.

2-Lightweight Design:

Despite the high load requirements, the crate had to remain lightweight enough for efficient handling and transport. Striking a balance between structural integrity and weight efficiency was critical in the design process.

3-Welding and Heat Treatment:

The fabrication process involved complex welding and heat treatment procedures. Precision was vital to ensure that the materials could withstand the immense loads while maintaining their integrity, especially at the joints and welded areas.

4-Carrying Method in Compliance with Rail Standards:

The crate had to comply with the Association of American Railroads (AAR) rail shipping standards, which required specific handling methods. The design called for the use of four slings and shackles for lifting, ensuring that the crate could be safely handled and transported without compromising the integrity of the turbine bearing or the crate.

Design and Standards

The shipping crate was designed in accordance with the AAR Part 1 standards, which mandate that all cargo measurement systems be capable of withstanding the following forces simultaneously:

- 3g Longitudinal Acceleration (30 tons Load)

- 2g Lateral Acceleration (20 tons Load)

- 2g Vertical Acceleration (20 tons Load)

By adhering to these stringent standards, the crate was engineered to safely withstand a total load of 36 tons, ensuring the secure transport of the turbine bearing without risk of damage during transit.