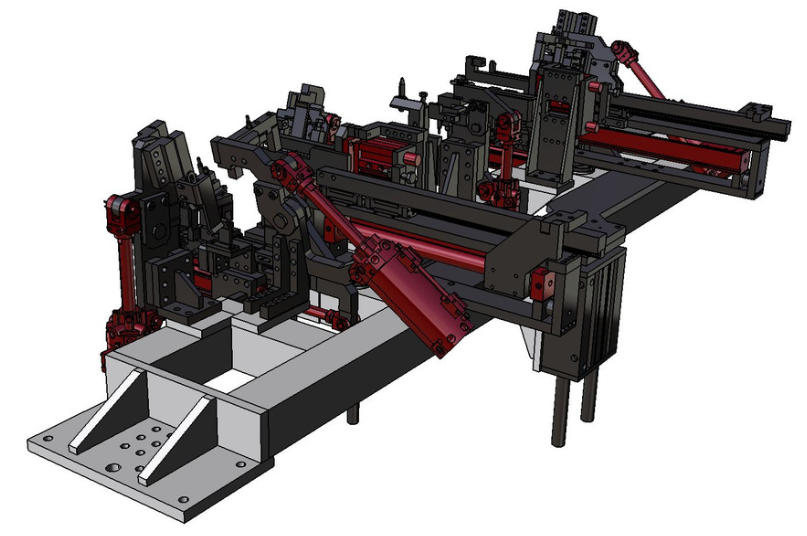

Project Description

Welding fixtures are one of the most important devices for an automotive body welding assembly line to achieve the required accuracy on the welded panels and therefore a great smooth look on the finished car’s body. Level of automation on a welding fixture could vary from a fully automated to a manually actuated one. We started from an initial design review with the customer to highlight goals of the fixture, welding access (gun access), safety controls, timing and costs. This fixture has approximately 120 machined components and 50 purchased ones. Pneumatic safety controls were used to actuate the fixture.